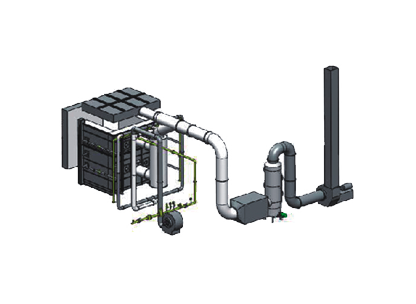

JR-NJW-C2 horizontal and vertical component test furnace 1.5x1.5x1.5m

Classification: Material Combustion  Download

Download

【Test items】

Fire resistance time of building material industry standard parts and other test pieces losing integrity and heat insulation

【Applicable standards】

GB/T 9978 Fire-resistance tests-Elements of building construction

ISO 834-1 Fire-Resistance Tests-Element of Building Construction-Part1:General Requirements

GBT 26784 Fire resistance test for elements of building construction-Alternative and additional procedures-Part 4.1: Hydrocarbon temperature rise curve

GBT 26784 Fire resistance test for elements of building construction-Alternative and additional procedures-Part 4.5: Tunnel temperature rise curve

The same temperature rise as American standard, European standard and other foreign standards can be extended

【Technical Parameters】

● Furnace type: Horizontal and vertical test furnace

● Kiln size: 1.5m × 1.5m × 1.5m

● Number of furnace doors: 1 fully sealed furnace door + 1 sample furnace door + 1 fully sealed sample cover;

● Fuel: Liquefied petroleum gas or natural gas

● Maximum operating temperature: 1300 ℃

● Number of burners: 4 sets

● Exhaust air volume: ≈12000Nm3 / h

● Furnace wall temperature rise: < room temperature + 40 ℃ (area around non burner and observation window)

● Thermal insulation material: Ceramic fiber module is used for furnace wall; Refractory brick is used for furnace bottom;

● Thermocouple: 4 thermocouples in the furnace; 10 thermocouples at back temperature,

● One mobile thermocouple and one environmental thermocouple.

● Thermocouples meet the requirements of the GB9978.1 standard and the nickel-chromium-nickel-silicon (K-type) thermocouples that meet the requirements of GB / T16839.1. The test accuracy of the thermocouple in the furnace is ± 10 ℃

Environmental and back-fired thermocouple test accuracy ± 2 ° C, mobile thermocouple test accuracy ± 4 ° C. The back surface test reserves 20 interfaces, and at the same time, it can measure the position of 20 thermocouple interfaces for the back surface temperature.

● Fire closing window: 2 sets of back wall of furnace body

Combustion control form: Proportional combustion, kiln pressure automatic control, temperature automatic regulation, temperature curve program control, computer-aided management

Smoke exhaust form: Mechanical smoke exhaust at the back, connected to water washing and dedusting tower.